Harness the power of Digital Twin Technology to elevate your business. Gain real-time insights for enhanced customer satisfaction, predictive maintenance, and personalized experiences. Improve product quality using quality monitoring tools, data analysis, and proactive quality assurance. Reduce time-to-market with accelerated product development, streamlined production processes, and faster go-to-market strategies. Embrace sustainable operational practices, increase supply chain resilience, and explore new business models. Boost operational efficiency, productivity, and competitiveness. Dive deeper into the world of Digital Twin Technology to uncover a multitude of transformative benefits waiting to be harnessed.

Key Takeaways

- Real-time insights for improved product performance and quality monitoring.

- Accelerated product development with faster time to market and streamlined production processes.

- Sustainable operational practices through material swapping and energy efficiency enhancements.

- Increased supply chain resilience with real-time visibility and proactive risk management.

- Facilitating new business models and revenue opportunities through digital twin analytics.

Enhanced Customer Satisfaction

Enhancing customer satisfaction through digital twin technology involves providing real-time insights into product performance and usage, ultimately leading to improved quality and increased loyalty. By leveraging digital twins, companies can enhance customer engagement by offering personalized experiences tailored to individual preferences and needs. This level of customization allows for a more intimate interaction between the customer and the product, fostering a sense of connection and loyalty.

Through predictive maintenance enabled by digital twins, customers can rely on products that consistently perform at their best, resulting in heightened satisfaction with their purchases. Additionally, by incorporating customer feedback and behavior analysis into digital twin models, companies can fine-tune their offerings to better meet consumer demands. This targeted approach not only improves product quality but also ensures that customers feel valued and understood, further enhancing their overall satisfaction and driving increased engagement with the brand.

Improved Product Quality

With digital twin technology, you can utilize quality monitoring tools that continuously assess product performance based on real-time operational data. This data analysis enables you to identify potential issues early on, leading to proactive quality improvements throughout the product development lifecycle. By leveraging these tools, companies can guarantee higher product quality standards, reduce defects, and enhance overall customer satisfaction.

Quality Monitoring Tools

Real-time quality monitoring tools enabled by digital twin technology are revolutionizing product quality across various industries such as automotive, chemicals, and medical devices. These tools provide capabilities for predictive maintenance and performance optimization by leveraging real-world operational data. Through quality assurance and anomaly detection, digital twins offer a proactive approach to identifying issues before they impact product quality, ensuring continuous enhancements.

Industries are increasingly leveraging digital twin technology to gather real-time data, enabling generational improvements in product quality. By analyzing data collected through digital twins, companies can optimize performance, streamline operations, and enhance their value chains. This data-driven approach informs new product development, driving innovation and efficiency.

Moreover, the use of digital twins facilitates enhanced product design and development processes, offering a competitive edge and significant time and cost savings. By incorporating quality monitoring tools into digital twin frameworks, industries can achieve higher standards of product quality and operational excellence.

Real-time Data Analysis

Analyzing real-time data through digital twin technology plays a pivotal role in enhancing product quality through continuous insights and performance optimizations. By leveraging predictive maintenance capabilities, digital twins enable industries like automotive, chemicals, and high-tech to detect potential issues before they escalate, ensuring uninterrupted operations and improved product reliability. Through real-time data analysis, companies can monitor performance metrics closely, identify patterns, and proactively address any deviations to maintain peak product quality standards.

Moreover, digital twins aid in performance optimization by capturing and analyzing data on asset performance and production processes. This data collection allows businesses to pinpoint inefficiencies, streamline operations, and enhance overall productivity. By utilizing digital twin technology, industries can expedite product development cycles, leading to faster time-to-market and substantial cost savings. Embracing real-time data analysis through digital twins not only refines existing products but also facilitates the creation of innovative solutions that align with evolving customer demands.

Reduced Time to Market

By utilizing digital twin technology, you can accelerate your product development process, allowing for quicker iterations and innovations. This technology streamlines production processes by providing real-time data and simulations to optimize your products efficiently. Ultimately, leveraging digital twins enables you to implement a faster go-to-market strategy, giving you a competitive edge in dynamic market landscapes.

Accelerated Product Development

Digital twin technology plays an essential role in accelerating product development by greatly reducing the time it takes to bring a product to market. Through iterative prototyping and agile development methodologies, companies utilizing digital twins experience faster iteration cycles, enabling quicker innovation and product releases. By leveraging real-world operational data, organizations gain valuable insights that inform new product development, enhancing speed and efficiency in bringing products to market.

The continuous feedback loop provided by digital twins contributes to improved product quality, leading to generational product enhancements and faster development timelines. This proactive approach helps companies avoid late-stage redesigns, ensuring that products are market-ready in a timely manner. Overall, the integration of digital twin technology streamlines the product development process, allowing for quicker adaptation to market demands and ultimately accelerating the journey from concept to consumer.

Streamlined Production Processes

Implementing digital twin technology in manufacturing operations greatly streamlines production processes, leading to a notable reduction in time to market for companies. By leveraging predictive maintenance and operational optimization, digital twins offer real-time insights that enhance efficiency and drive faster product launches. Here are some key ways digital twins contribute to streamlined production processes:

- Real-Time Monitoring: Digital twins enable continuous monitoring of manufacturing operations, allowing for quick identification and resolution of issues.

- Predictive Analytics: Utilizing data from digital twins helps predict maintenance needs, preventing unexpected downtime and delays in production.

- Workflow Optimization: Digital twins optimize production workflows by identifying bottlenecks and suggesting improvements for smoother processes.

- Iterative Design: Companies benefit from iterative design improvements facilitated by digital twins, resulting in faster iterations and product enhancements.

- Cost Savings: Reduced time to market achieved through digital twins not only accelerates product releases but also leads to significant cost savings, providing a competitive advantage in the market.

Faster Go-To-Market Strategy

Utilizing digital twin technology results in a faster go-to-market strategy by significantly reducing the time needed to launch new products and innovations. By leveraging digital twins, companies can expedite their product development cycles, enabling quicker market releases and entry. This accelerated time to market not only helps businesses keep pace with competitors but also allows them to respond more effectively to consumer demands. Through real-time insights and data analytics facilitated by digital twins, companies can streamline their product development processes, saving important time in bringing their offerings to market. Additionally, digital twins assist in avoiding last-minute redesigns, ensuring that products are market-ready promptly. This enhanced efficiency in product positioning and market research translates into improved business agility and competitiveness, making it easier for companies to meet market demands swiftly and effectively. Essentially, the adoption of digital twin technology plays a significant role in expediting the go-to-market strategy and enhancing overall business performance.

Sustainable Operational Practices

Enhancing sustainability through operational practices is facilitated by the integration of digital twin technology, enabling companies to make informed decisions based on real-time data and predictive analytics. Digital twins play a pivotal role in driving sustainable operational practices, focusing on reducing environmental impact and promoting the use of sustainable materials. Here are five key points to keep in mind:

- Material Swapping: Companies can utilize digital twins to swap traditional materials for sustainable alternatives, thereby reducing their carbon footprint.

- Energy Efficiency: Digital twins help enhance energy efficiency within operations, contributing to overall sustainability efforts.

- Production Capacity: Leveraging digital twins can improve production capacity while maintaining a focus on sustainability.

- Real-time Monitoring: The technology allows for real-time monitoring of environmental metrics, aiding in making proactive sustainability decisions.

- Waste Reduction: Digital twins provide valuable insights that enable companies to reduce waste and promote eco-friendly practices effectively.

Increased Supply Chain Resilience

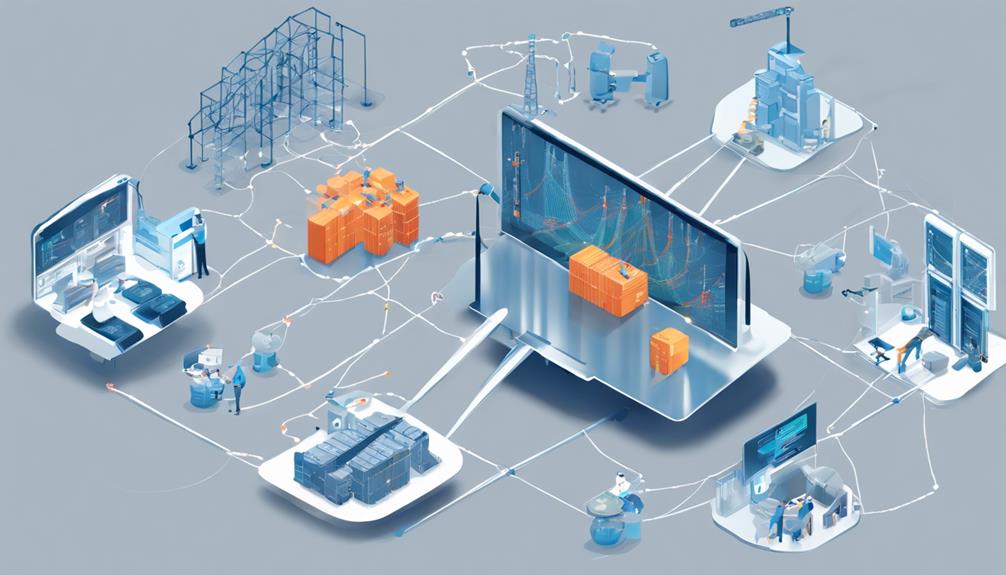

Digital twin technology greatly enhances supply chain resilience by offering real-time visibility and actionable insights into operations. With the ability to monitor processes and performance continuously, companies can proactively identify and address potential risks before they escalate, thereby improving risk management. The real-time data provided by digital twins allows for quick decision-making, enabling companies to adjust operations promptly and enhance supply chain agility. By leveraging digital twin insights, organizations can optimize lead times, streamline workflows, and minimize disruptions, ultimately increasing the overall resilience of the supply chain.

Furthermore, the enhanced agility and resilience facilitated by digital twins play an important role in adapting to dynamic market conditions. Companies can better respond to changes in demand, supply shortages, or unforeseen events by utilizing the predictive capabilities of digital twin technology. This proactive approach to supply chain management mitigates risks, improves operational efficiency, and fosters a more robust and adaptable business ecosystem.

Facilitated New Business Models

By harnessing digital twin technology, companies can revolutionize their business models to capitalize on new opportunities and maximize revenue potential through innovative data-driven strategies. Here are some key points to take into account:

- Digital twin technology enables the creation of revenue opportunities by offering products as a service, leveraging valuable data insights.

- Companies can provide customers with value-added services based on digital twin analytics, enhancing customer experience and loyalty.

- Subscription-based models, made possible by digital twins, allow businesses to establish recurring revenue streams and build long-term relationships with clients.

- Enhanced customer anticipation and inventory management are facilitated by digital twin technology, leading to increased business value and operational efficiency.

- Leveraging the data insights from digital twins, companies can develop innovative revenue streams and stay ahead of the competition in dynamic markets.

Digital twin technology is not just about creating digital replicas; it's about transforming the way businesses operate, interact with customers, and generate revenue.

Enhanced Operational Efficiency

Real-time monitoring of asset and production performance through digital twin technology drives significant operational efficiency gains for businesses. By harnessing the power of digital twins, organizations can optimize their processes by identifying bottlenecks and implementing targeted solutions promptly. This proactive approach not only enhances performance monitoring but also streamlines value chain operations, improving overall efficiency.

Furthermore, digital twins enable predictive analytics and real-time monitoring, empowering businesses to make data-driven decisions that lead to maintenance improvements. This capability not only enhances operational efficiency but also contributes to cost savings and time efficiency. By leveraging digital twin technology, companies can proactively address potential issues before they escalate, ensuring smooth operations and optimizing resource utilization.

In essence, the integration of digital twin technology into operations offers a holistic approach to enhancing operational efficiency through process optimization and performance monitoring. This strategic utilization of digital twins paves the way for continuous improvement and sustainable growth in today's dynamic business landscape.

Boosted Productivity

Improving productivity through the utilization of digital twin technology involves enhancing control and efficiency in operations. By leveraging digital twins, you can experience significant efficiency gains and enhanced insights, ultimately boosting your productivity. Here are five key ways digital twins contribute to increased productivity:

- Real-time monitoring and predictive analytics provide better control over processes.

- Streamlined value chain operations lead to optimized productivity.

- Remote monitoring capabilities reduce the need for on-site interventions, saving time and resources.

- Augmented reality guidance for maintenance enhances first-time-fix rates, minimizing downtime.

- Knowledge retention through digital twins helps mitigate productivity losses due to turnover.

These benefits highlight how digital twins not only improve operational efficiency but also play an essential role in driving productivity growth across various industries. Embracing this technology can revolutionize how businesses operate, leading to enhanced performance and competitiveness.

Frequently Asked Questions

How Can Digital Twin Technology Improve Predictive Maintenance?

To enhance predictive maintenance through digital twin technology, start with thorough equipment monitoring. By continuously tracking asset performance, you can pinpoint deviations and potential failures early. This proactive approach enables fault prediction by analyzing patterns and anomalies. Utilize real-time data to create accurate predictive models for maintenance needs. Incorporating digital twins optimizes maintenance schedules and prolongs asset lifespan, ultimately reducing downtime and costs.

What Role Does Data Security Play in Digital Twin Implementation?

In digital twin implementation, data security is paramount. Safeguarding data privacy and mitigating cybersecurity risks are pivotal in protecting sensitive information. Robust security protocols are essential to prevent unauthorized access and guarantee data integrity. By managing data quality effectively, bad data can be excluded, and information gaps filled, enhancing the accuracy of digital twin models. Training your team adequately to work with digital twins maximizes benefits and minimizes risks associated with data security breaches.

Can Digital Twins Be Integrated With Existing IT Systems?

Yes, digital twins can be integrated with existing IT systems, but challenges may arise due to compatibility issues. In fact, a study found that 65% of companies face integration challenges when implementing digital twins. These issues stem from differences in data formats, protocols, and system architectures. Overcoming compatibility hurdles requires thorough planning, collaboration between IT teams, and possibly the use of middleware solutions to facilitate seamless integration.

How Does Digital Twin Technology Impact Workforce Training?

Incorporating virtual simulations and interactive learning, digital twin technology revolutionizes workforce training. It fosters enhanced skill development through immersive experiences, enabling trainees to grasp complex concepts in a practical, hands-on manner. By replicating real-world scenarios, digital twins provide a platform for continuous learning and improvement. This approach not only enhances knowledge retention but also boosts performance levels, ultimately leading to a more proficient and adaptable workforce.

Are There Industry-Specific Challenges When Adopting Digital Twins?

When adopting digital twins, industries face unique challenges. In manufacturing, efficiency hinges on overcoming interoperability issues between machinery and software systems. Healthcare monitoring requires addressing data privacy and security concerns for patient care. Each sector must navigate hurdles specific to their operations to fully leverage the benefits of digital twin technology. By addressing these industry-specific challenges head-on, organizations can maximize the potential of digital twins in revolutionizing their workflows.