Digital twin technology is a cutting-edge concept that has gained significant traction in recent years, particularly in the energy sector. Essentially, a digital twin is a virtual replica of a physical system or process, such as a building, a machine, or an entire energy system. This virtual representation is created by collecting and integrating real-time data from sensors, IoT devices, and other sources, allowing for a comprehensive and accurate simulation of the physical system.

The digital twin is not just a static model; it is a dynamic and evolving representation that mirrors the behavior and performance of its physical counterpart in real time. This means that any changes or anomalies in the physical system can be immediately reflected in the digital twin, enabling proactive monitoring, analysis, and decision-making. With the help of advanced analytics, machine learning, and artificial intelligence, digital twins can provide valuable insights and predictions to optimize the performance, efficiency, and sustainability of energy systems.

In essence, digital twin technology offers a powerful tool for energy professionals to gain a deeper understanding of their systems, identify opportunities for improvement, and make informed decisions to enhance energy efficiency and sustainability.

Key Takeaways

- Digital twin technology creates a virtual replica of physical assets, processes, or systems to monitor, analyze, and optimize their performance.

- Digital twin technology plays a crucial role in improving energy efficiency by providing real-time data, predictive analytics, and simulation capabilities.

- Implementing digital twin technology in energy systems involves integrating IoT sensors, data analytics, and machine learning algorithms to create a digital replica for monitoring and optimizing energy usage.

- Using digital twin technology for energy efficiency offers benefits such as improved operational efficiency, reduced downtime, predictive maintenance, and optimized energy consumption.

- Case studies demonstrate successful applications of digital twin technology in energy efficiency, including optimizing building energy usage, monitoring renewable energy systems, and improving industrial process efficiency.

The Role of Digital Twin Technology in Energy Efficiency

Digital twin technology plays a crucial role in driving energy efficiency across various sectors, including buildings, industrial facilities, and power plants. By creating a virtual replica of energy systems, organizations can gain unprecedented visibility into the performance and operation of their assets. This visibility enables them to identify inefficiencies, optimize processes, and reduce energy consumption and waste.

For example, in the context of building management, digital twins can provide facility managers with real-time insights into HVAC systems, lighting, and other energy-consuming equipment. By analyzing data from sensors and meters, digital twins can help identify patterns of energy usage, detect anomalies, and recommend adjustments to improve efficiency. Similarly, in industrial settings, digital twins can simulate complex manufacturing processes and equipment to identify bottlenecks, optimize production schedules, and minimize energy waste.

Furthermore, digital twin technology can enable predictive maintenance by monitoring the condition and performance of energy assets in real time. By analyzing data from sensors and historical maintenance records, organizations can anticipate equipment failures, schedule maintenance proactively, and avoid costly downtime. Ultimately, digital twin technology empowers organizations to make data-driven decisions that lead to significant improvements in energy efficiency and operational performance.

Implementing Digital Twin Technology in Energy Systems

Implementing digital twin technology in energy systems requires a strategic approach and careful consideration of various factors. The first step is to define the scope and objectives of the digital twin initiative, including the specific assets or processes to be replicated and the desired outcomes in terms of energy efficiency and performance optimization.

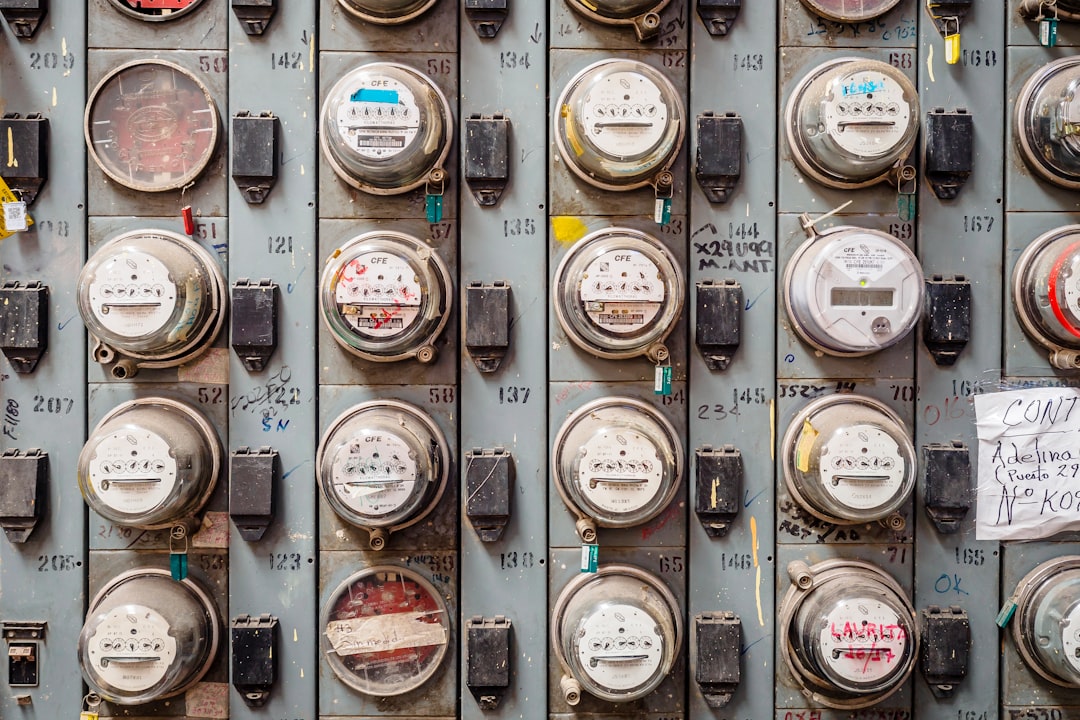

Next, organizations need to assess their existing data infrastructure and capabilities to ensure they have the necessary sensors, IoT devices, and data collection mechanisms in place. This may involve retrofitting existing assets with sensors or deploying new IoT devices to capture real-time data on energy consumption, equipment performance, environmental conditions, and other relevant parameters.

Once the data infrastructure is established, organizations need to integrate the collected data into a digital twin platform that can process, analyze, and visualize the information effectively. This typically involves leveraging advanced analytics tools, machine learning algorithms, and visualization techniques to create a dynamic and interactive representation of the physical system.

Furthermore, organizations need to ensure that their staff are adequately trained to interpret and utilize the insights generated by the digital twin. This may involve providing training on data analysis, visualization tools, and decision-making processes to empower employees to leverage the full potential of digital twin technology.

Finally, organizations should continuously monitor and refine their digital twin models based on new data and insights to ensure that they remain accurate and relevant. By iteratively improving the digital twin representation, organizations can drive continuous improvements in energy efficiency and operational performance.

Benefits of Using Digital Twin Technology for Energy Efficiency

| Benefits | Description |

|---|---|

| Real-time Monitoring | Allows for continuous monitoring of energy usage and performance. |

| Optimization | Enables optimization of energy systems and processes for improved efficiency. |

| Predictive Maintenance | Helps in predicting and preventing equipment failures, reducing downtime and maintenance costs. |

| Data-driven Insights | Provides valuable data-driven insights for informed decision-making. |

| Simulation and Analysis | Allows for simulation and analysis of different scenarios to identify energy-saving opportunities. |

The adoption of digital twin technology offers a wide range of benefits for organizations seeking to enhance energy efficiency in their operations. One of the primary benefits is improved visibility and understanding of energy systems, which enables organizations to identify inefficiencies and opportunities for optimization. By creating a virtual replica of their assets and processes, organizations can gain insights into energy consumption patterns, equipment performance, and environmental conditions that may impact efficiency.

Furthermore, digital twin technology enables proactive monitoring and predictive maintenance of energy assets, which can help organizations avoid costly downtime and reduce maintenance costs. By analyzing real-time data from sensors and historical maintenance records, organizations can anticipate equipment failures, schedule maintenance proactively, and optimize asset performance.

Another key benefit of digital twin technology is the ability to simulate “what-if” scenarios to evaluate the impact of potential changes on energy efficiency. Organizations can use digital twins to model different operating conditions, equipment configurations, or process adjustments to assess their potential impact on energy consumption and performance. This capability empowers organizations to make informed decisions about operational changes that can lead to significant improvements in energy efficiency.

Moreover, digital twin technology facilitates data-driven decision-making by providing actionable insights and recommendations based on real-time data analysis. By leveraging advanced analytics and machine learning algorithms, organizations can uncover hidden patterns in their data and identify opportunities for improvement that may have been overlooked using traditional methods.

Overall, the adoption of digital twin technology can lead to substantial improvements in energy efficiency, operational performance, and sustainability for organizations across various sectors.

Case Studies: Successful Applications of Digital Twin Technology in Energy Efficiency

Several organizations have successfully implemented digital twin technology to drive improvements in energy efficiency across different sectors. For example, a leading commercial real estate company deployed digital twins in its portfolio of buildings to optimize energy consumption and reduce operational costs. By creating virtual replicas of HVAC systems, lighting controls, and other building equipment, the company gained insights into energy usage patterns and identified opportunities for optimization. As a result, they were able to reduce energy consumption by 15% across their portfolio while improving occupant comfort.

In another case study, a major industrial manufacturer utilized digital twins to optimize the performance of its production facilities and reduce energy waste. By simulating complex manufacturing processes and equipment using digital twin technology, the company was able to identify bottlenecks, optimize production schedules, and minimize energy consumption. As a result, they achieved a 20% reduction in energy usage while increasing production output.

Furthermore, a utility company implemented digital twins in its power generation facilities to improve operational efficiency and reliability. By creating virtual replicas of turbines, boilers, and other critical equipment, the company gained real-time visibility into asset performance and condition. This enabled them to implement predictive maintenance strategies that reduced downtime by 30% and improved overall plant efficiency.

These case studies demonstrate the significant impact that digital twin technology can have on energy efficiency when implemented effectively. By leveraging real-time data analysis, predictive modeling, and simulation capabilities, organizations can achieve substantial improvements in energy consumption, operational performance, and cost savings.

Overcoming Challenges in Adopting Digital Twin Technology for Energy Efficiency

While digital twin technology offers compelling benefits for improving energy efficiency, organizations may face several challenges when adopting this innovative approach. One of the primary challenges is the complexity of integrating diverse data sources into a cohesive digital twin platform. Organizations may struggle to collect and integrate real-time data from various sensors, meters, and IoT devices across their energy systems. This challenge requires careful planning and investment in data infrastructure to ensure that all relevant data is captured effectively.

Another challenge is the need for advanced analytics capabilities to process and analyze the vast amounts of data collected from digital twins. Organizations may lack the necessary expertise or tools to derive actionable insights from their digital twin models. This challenge requires investment in analytics capabilities and training for staff to interpret and utilize the insights generated by digital twins effectively.

Furthermore, organizations may face resistance from employees who are unfamiliar with digital twin technology or skeptical about its potential benefits. Overcoming this challenge requires effective change management strategies to educate employees about the value of digital twins for improving energy efficiency and involve them in the implementation process.

Additionally, organizations may encounter challenges related to data privacy and security when collecting sensitive information from their energy systems for use in digital twins. Ensuring compliance with data protection regulations and implementing robust security measures is essential to address these concerns.

Overall, while there are challenges associated with adopting digital twin technology for energy efficiency, organizations can overcome these obstacles through careful planning, investment in capabilities, effective change management strategies, and a commitment to data privacy and security.

The Future of Energy Efficiency with Digital Twin Technology

Looking ahead, the future of energy efficiency with digital twin technology holds tremendous promise for organizations seeking to optimize their operations and reduce environmental impact. As advancements in IoT devices, sensors, and data analytics continue to evolve, organizations will have access to even more granular and real-time data to feed into their digital twin models. This will enable more accurate simulations and predictions about energy consumption patterns, equipment performance, and environmental impacts.

Furthermore, as artificial intelligence and machine learning technologies mature, digital twins will become even more sophisticated in their ability to analyze complex data sets and provide actionable insights for improving energy efficiency. Organizations will be able to leverage these advanced capabilities to drive continuous improvements in their operations while reducing costs and environmental footprint.

Moreover, as more organizations adopt digital twin technology for energy efficiency initiatives, there will be opportunities for collaboration and knowledge sharing across industries. Best practices for implementing digital twins in different sectors will emerge, leading to accelerated adoption and widespread benefits for energy efficiency.

In conclusion, the future of energy efficiency with digital twin technology is bright as organizations continue to leverage this innovative approach to optimize their operations and reduce environmental impact. With advancements in data collection technologies, analytics capabilities, and collaborative initiatives across industries, digital twins will play an increasingly vital role in driving sustainable energy practices for years to come.